Product center

Contact us

Changzhou boang import and export co. LTD

Contact person: manager wang

Phone: 13961432521

Telephone: 0519-85853682

Fax: 0519-85853682

Manager zhu: 13813676349

Email address: yhy2521@163.com

Address: group 9, caaoqiao village, xueyan town, wujin district, changzhou city

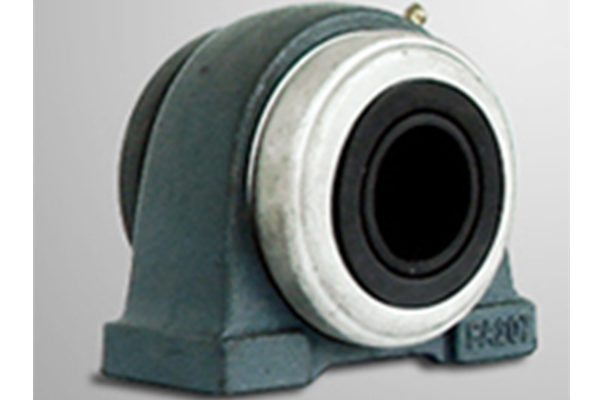

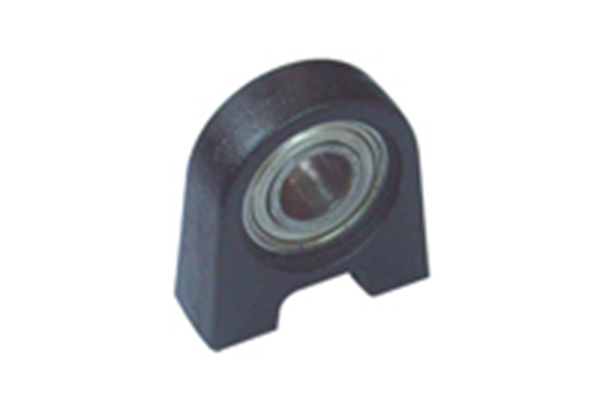

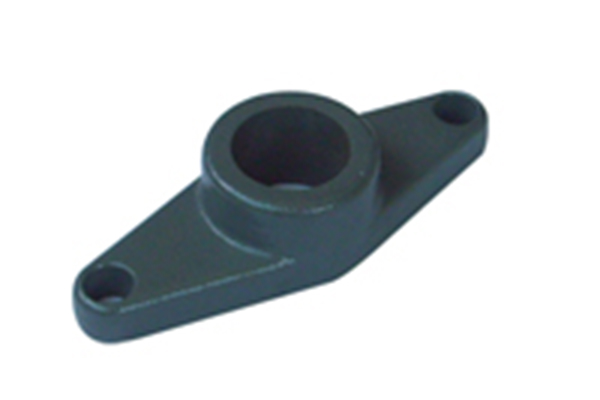

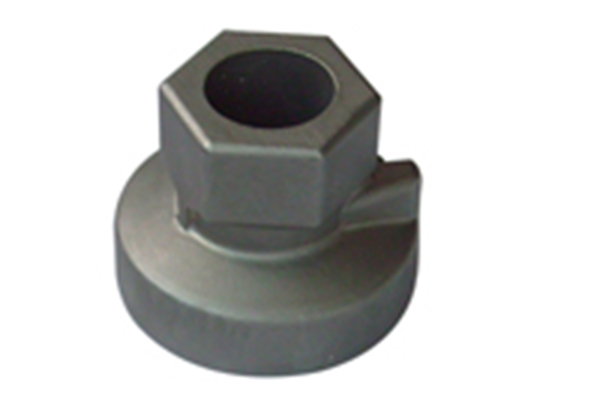

Introduction of zinc alloy bearings

Your location:homepage>Introduction of zinc alloy bearingsIntroduction of zinc alloy bearings

Release time:2020-05-23 Click on:times

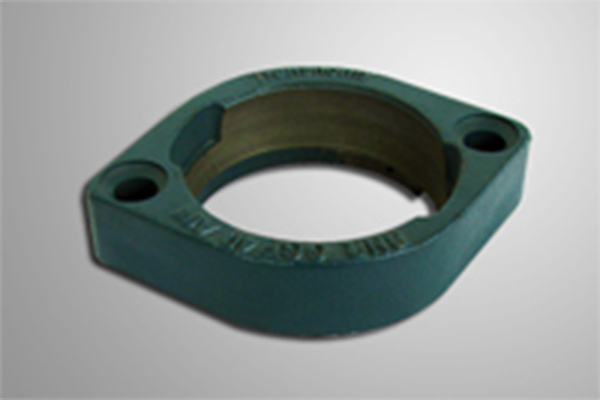

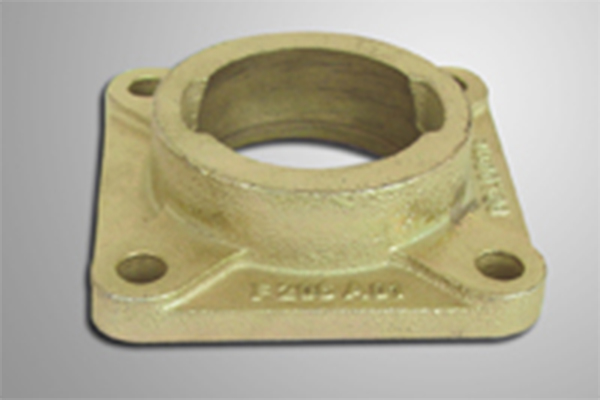

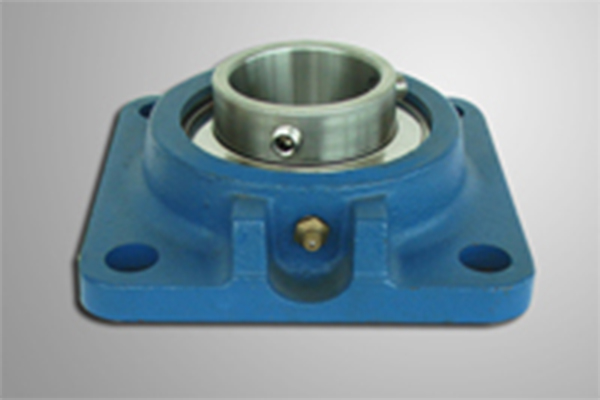

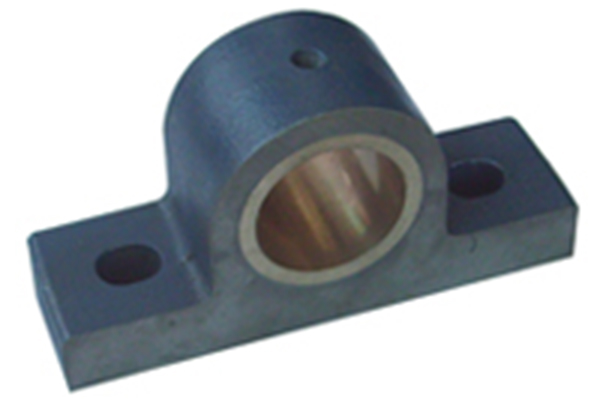

Zinc alloy bearing - new type of bearing alloy

An alloy consisting of zinc and other elements. Commonly added alloy elements are aluminum, copper, magnesium, cadmium, lead, titanium and so on. Zinc-based alloy low melting point, good fluidity, easy welding, brazing and plastic processing, corrosion resistance in the atmosphere, laminate easy recovery and remelting; However, due to the low creep strength, it is easy to change the size due to natural aging. Preparation by melting, die casting or pressure machining. According to the manufacturing process can be divided into cast zinc-base alloy and deformation zinc-base alloy.

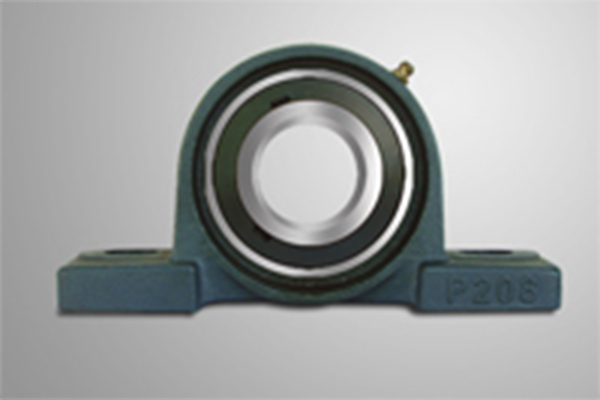

Compared to babbitt

In addition to having a significant cost performance advantage, it also has higher toughness, lower specific gravity and wider application range.

In comparison with bronze

1. The strength, hardness and allowable pressure are similar to that of aluminum bronze, and are widely higher than that of tin and lead, etc., and the allowable speed is similar to that of aluminum bronze. It can completely meet the use conditions of bearing bearing and other independent anti-friction and anti-wear parts.

2. Strong affinity for lubricating oil, better self-lubrication, and its metallurgical characteristics (low melting point, not easy to metallurgical combination with the steel shaft), so the use of strong adhesion, anti-friction wear characteristics are more prominent.

3. Low coefficient of friction, wear and tear, so the service life is longer. Under the same conditions of use, generally in the copper tile more than times, so as to reduce the procurement cost of accessories.

4. High thermal conductivity. ZCuAl0Fe3 =59), fast heat dissipation, slow and low surface temperature rise, providing better protection against paired friction.

5. Low material density (ZZnAl27Cu2Mg =5g/cm3), light weight (same type, same specification, light weight /3), easy to install, easy to maintain.

6. Has the high damping characteristic, reduces the vibration anti - noise.

You might also be interested

reading